Just Krys

From Grandma's House

3D Printing

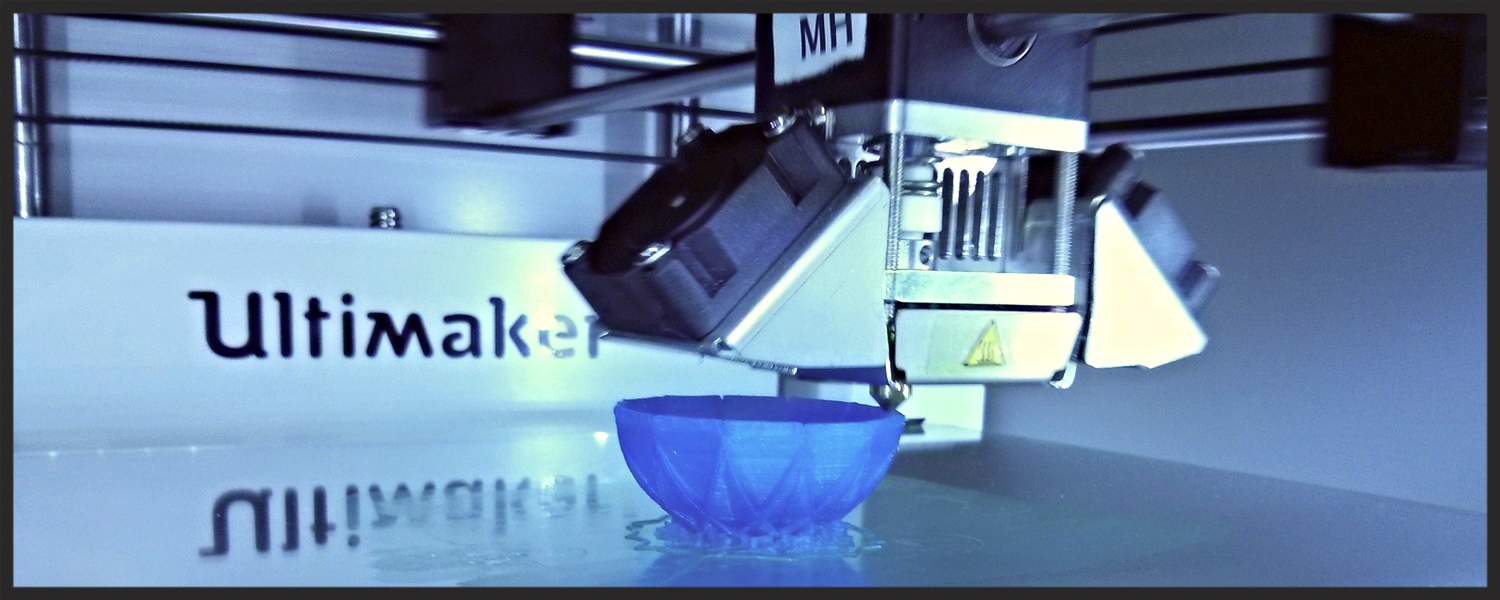

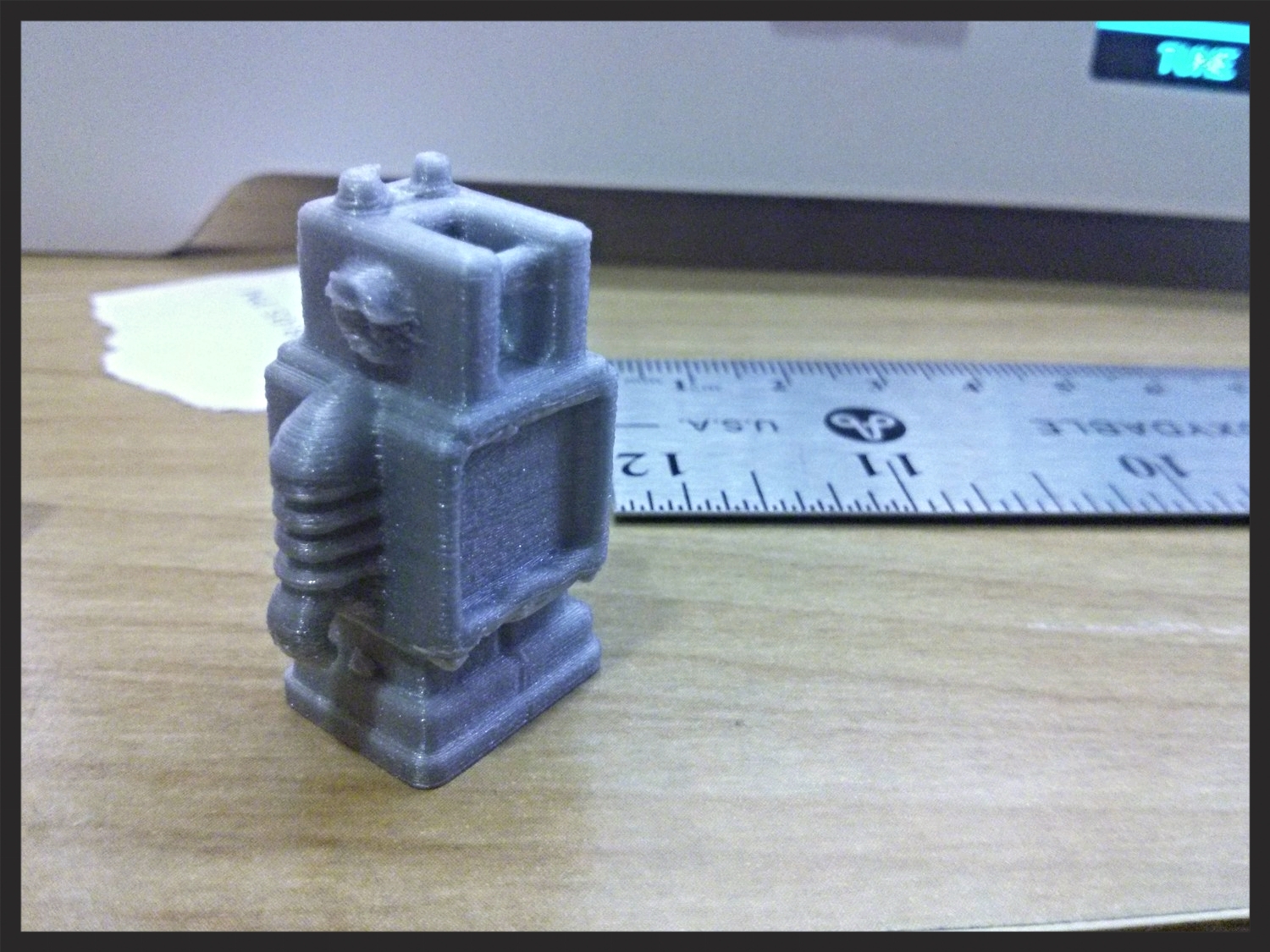

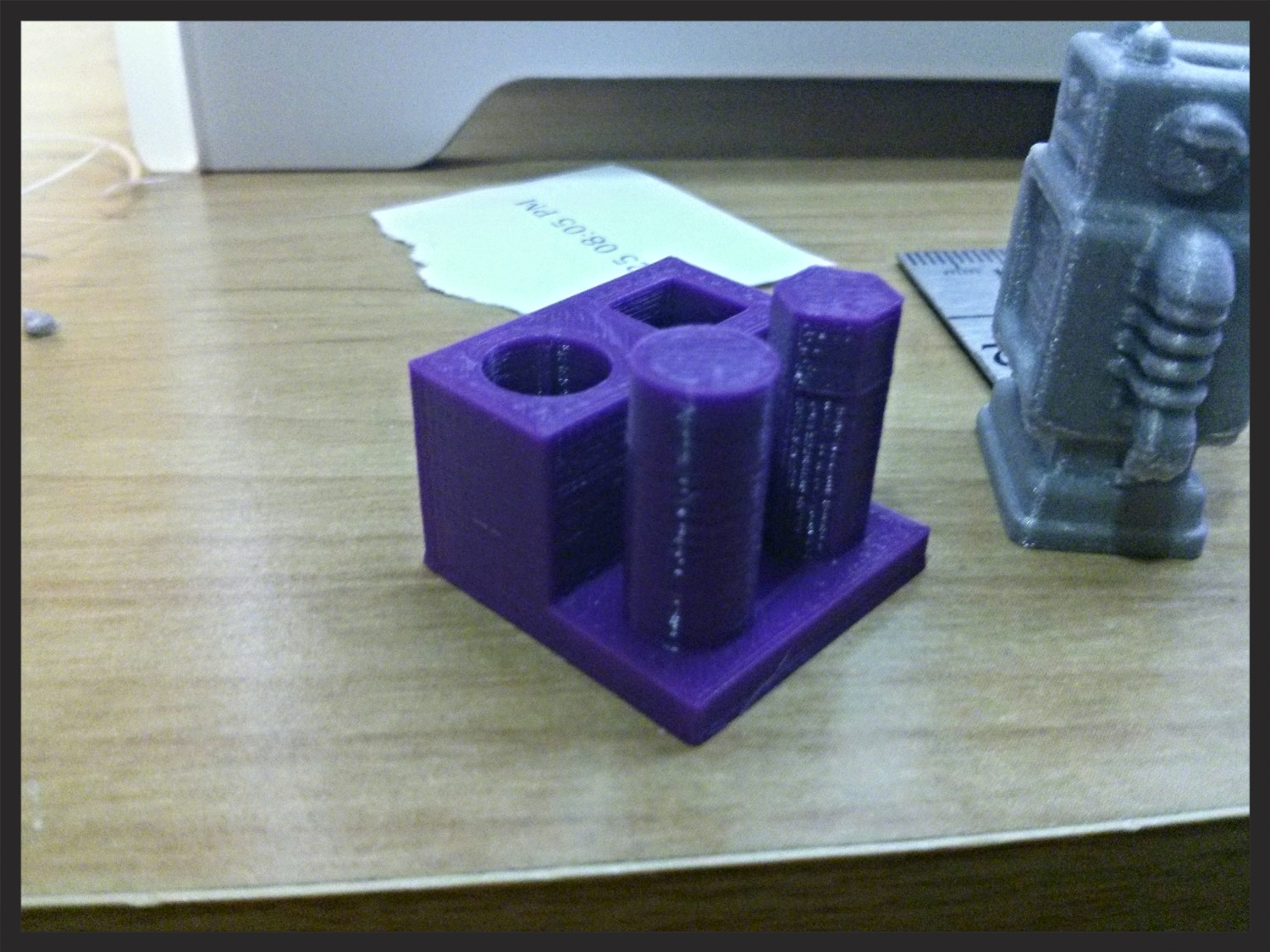

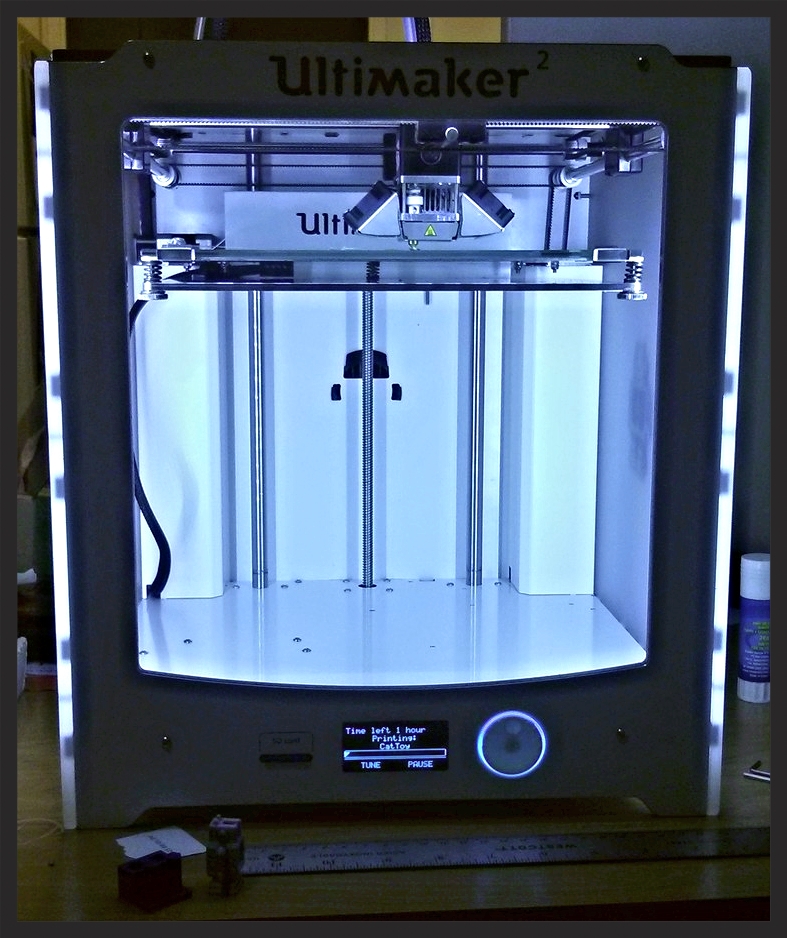

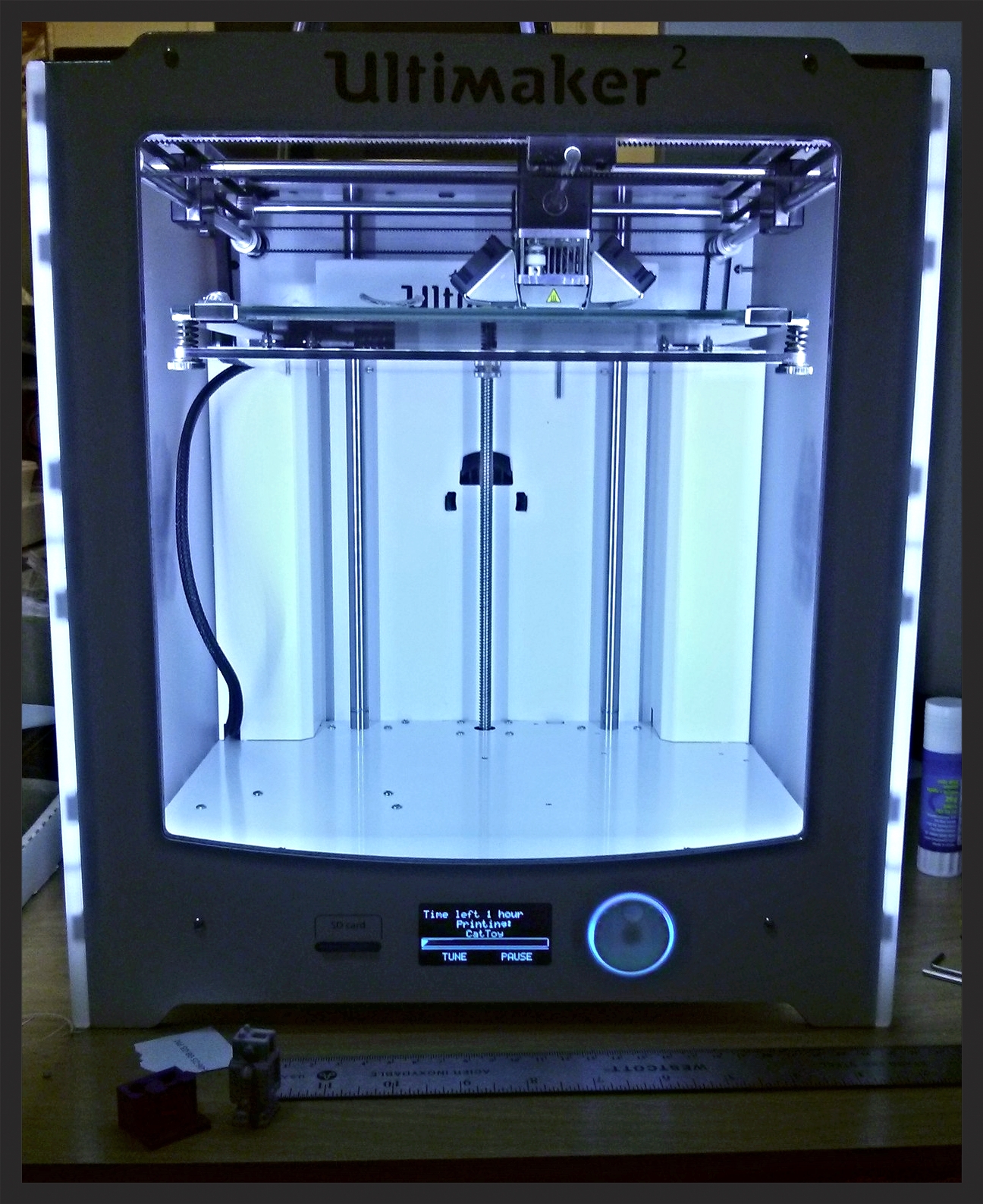

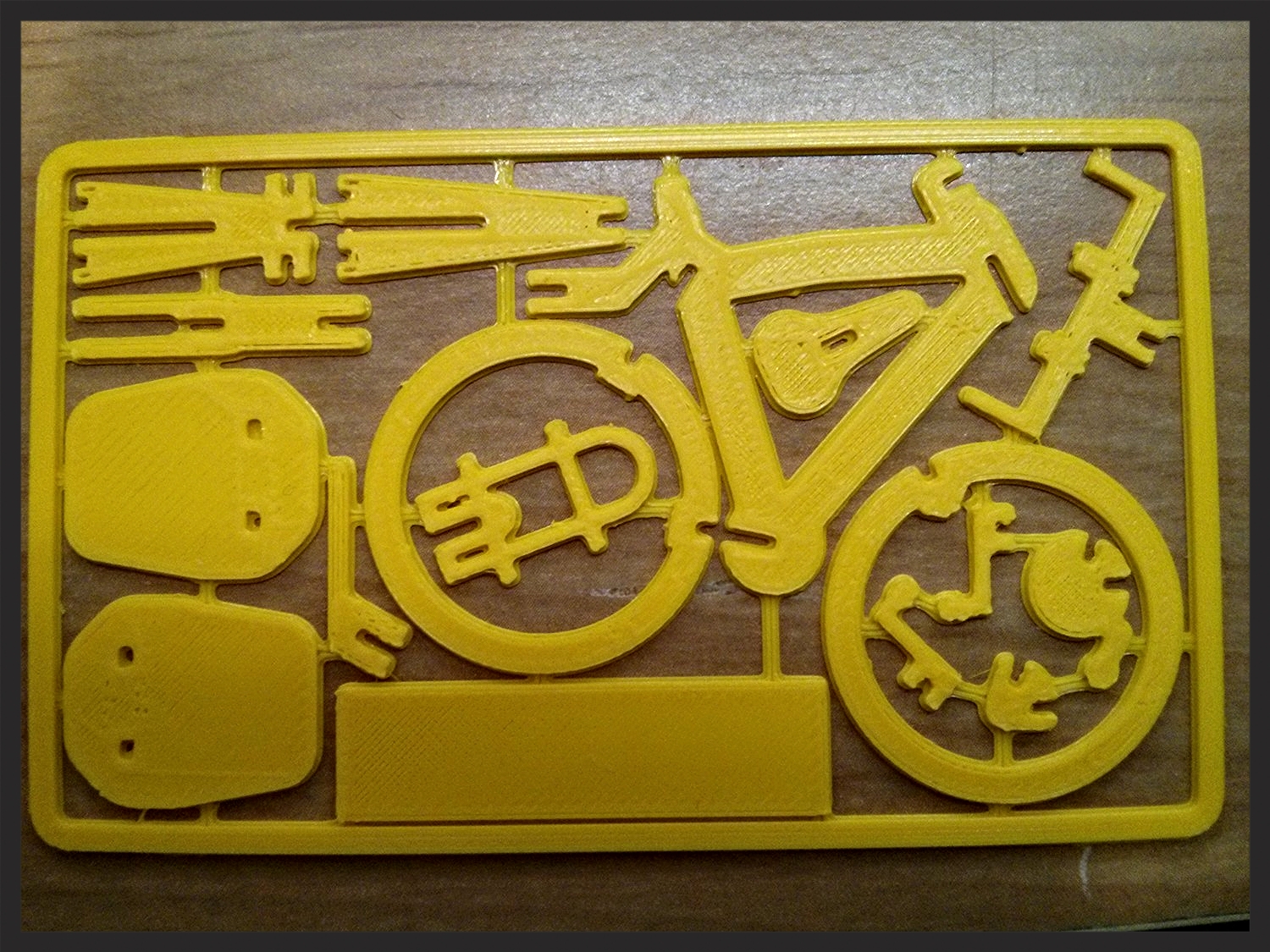

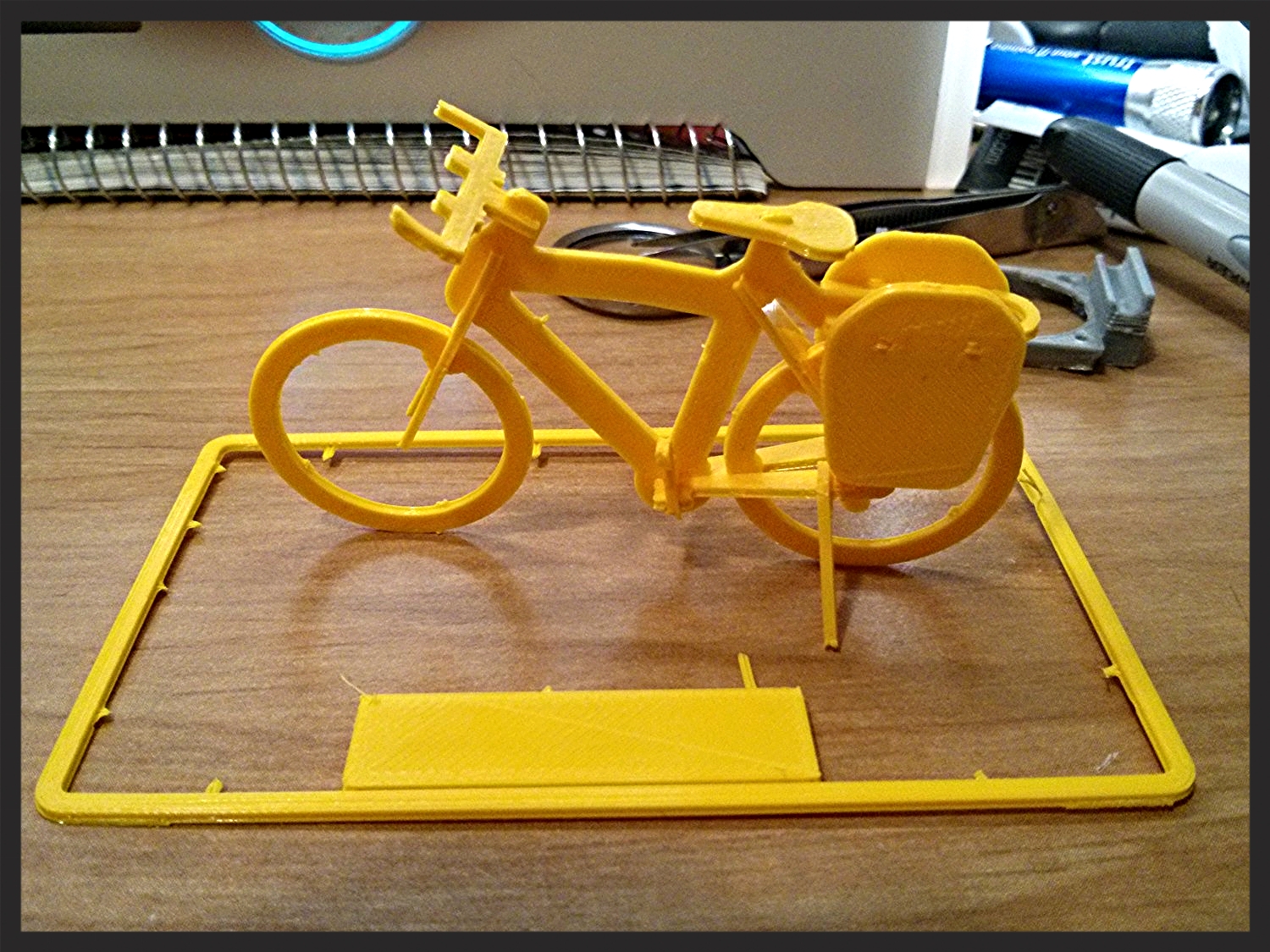

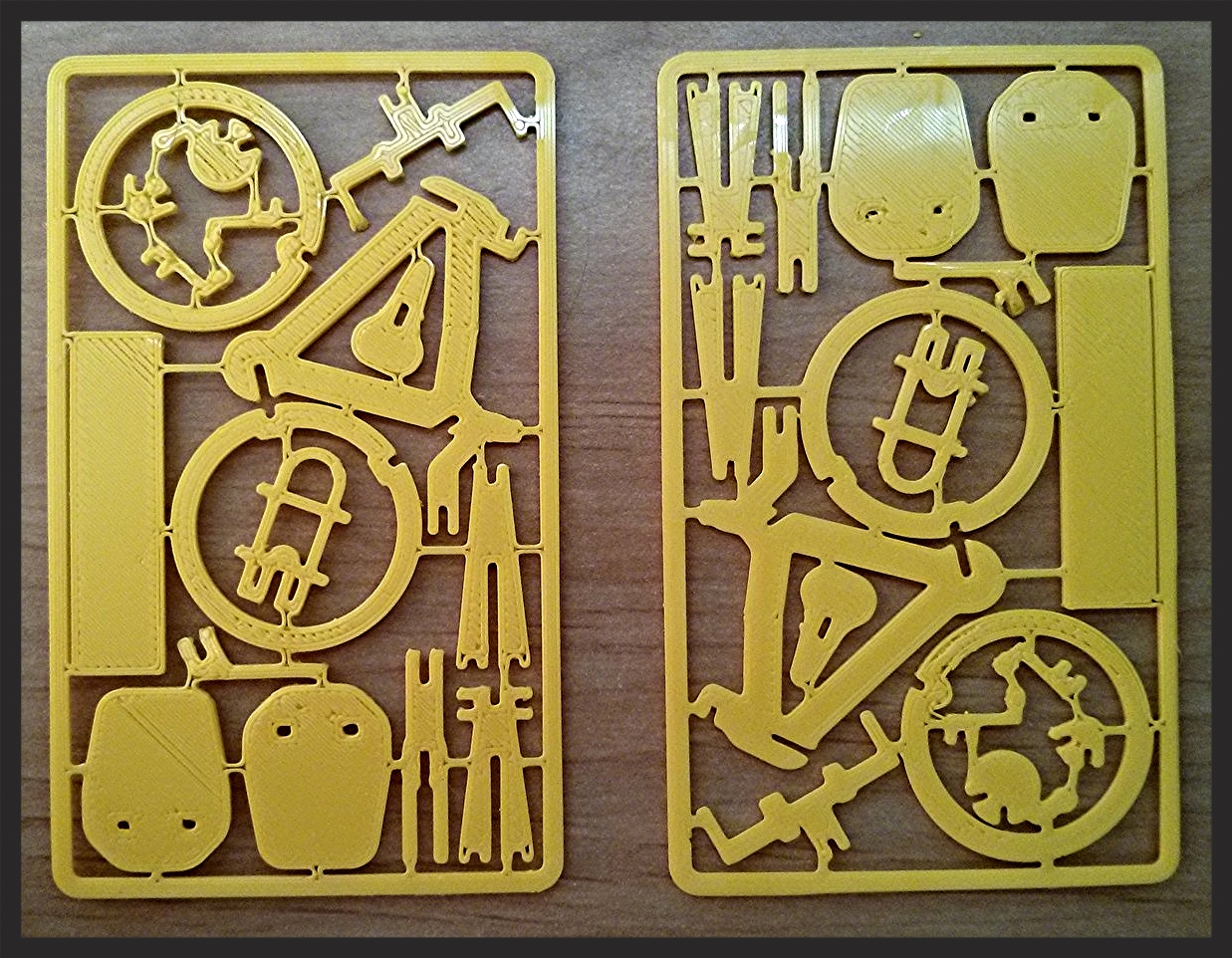

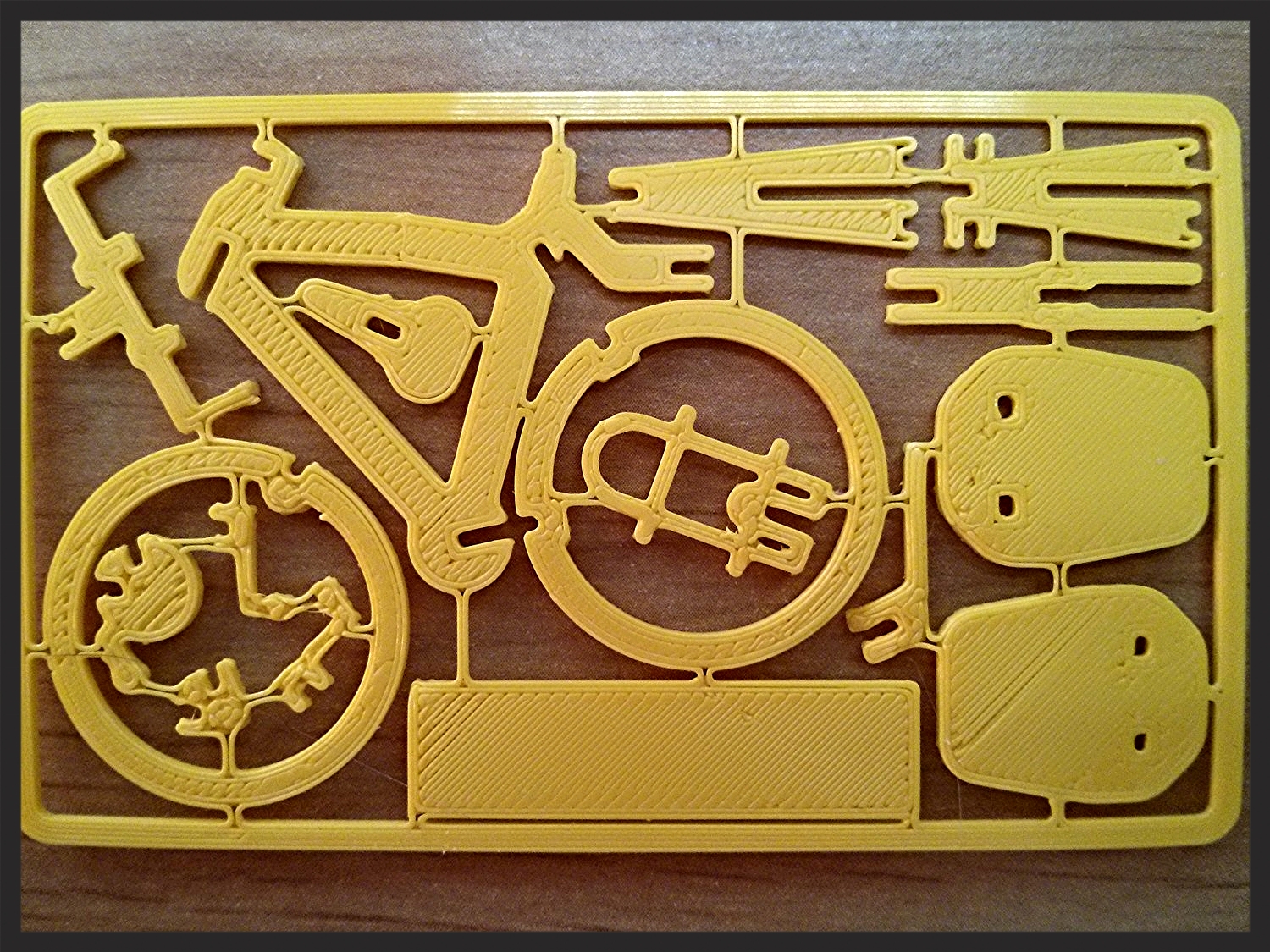

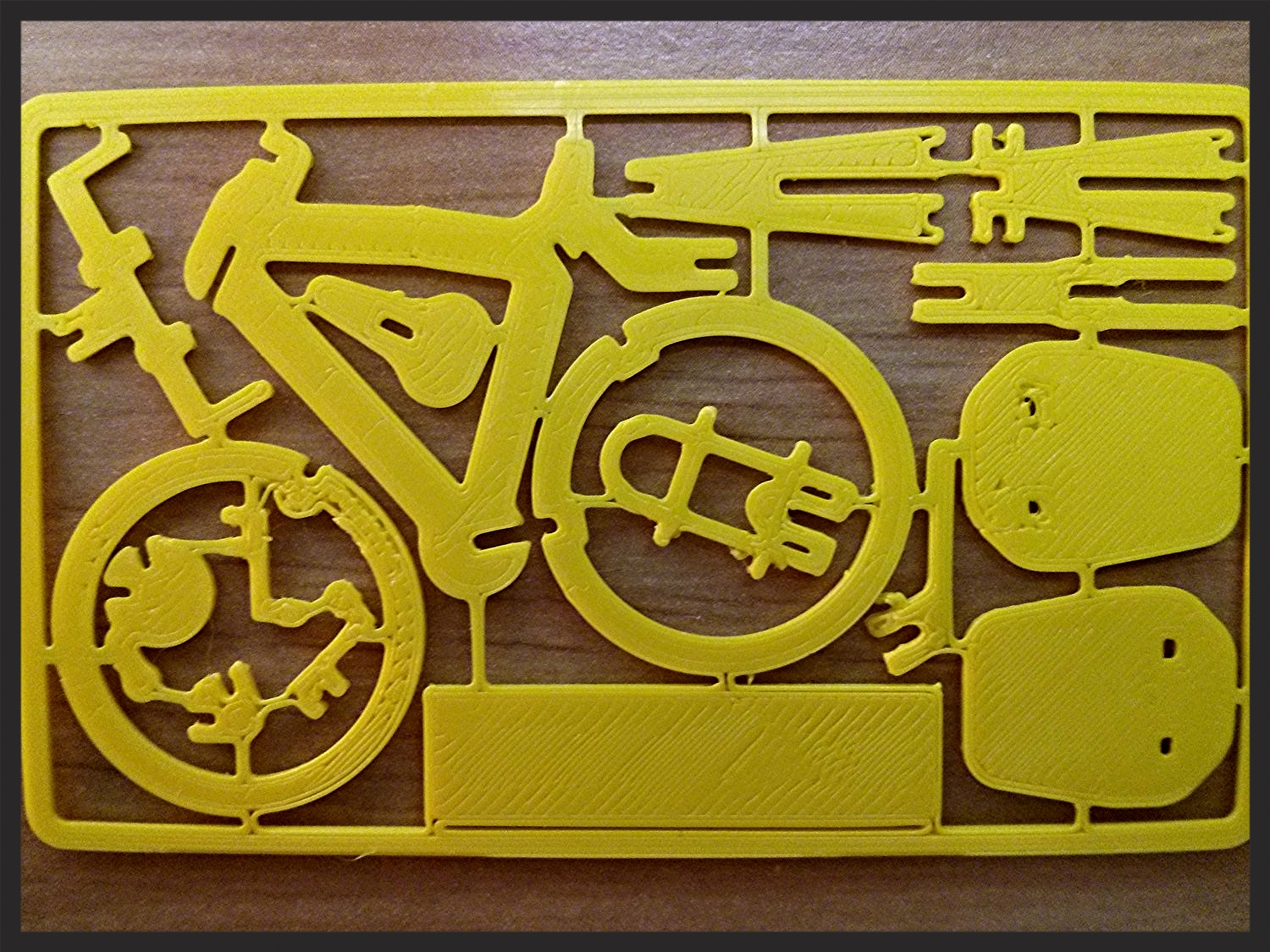

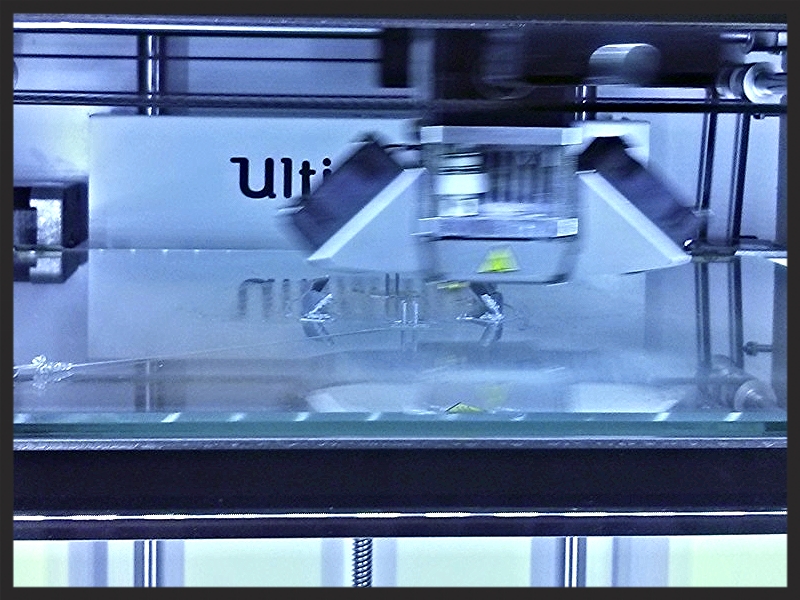

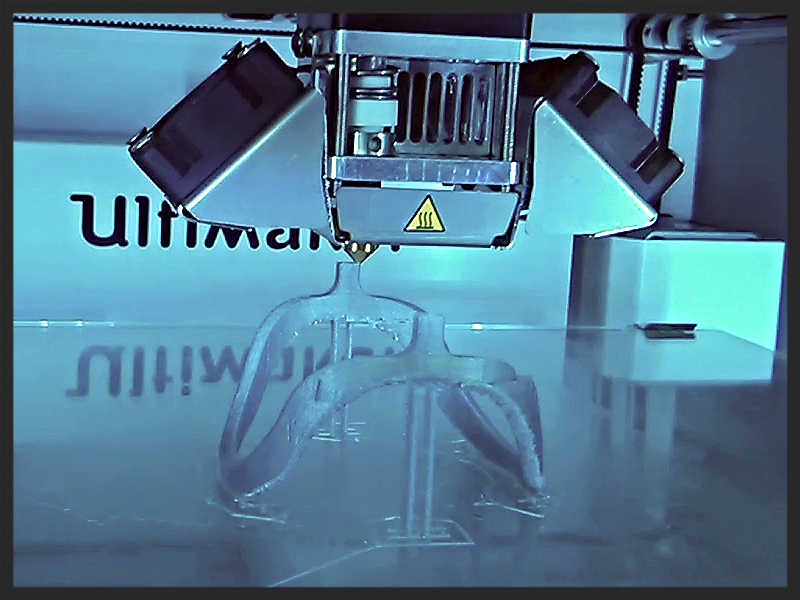

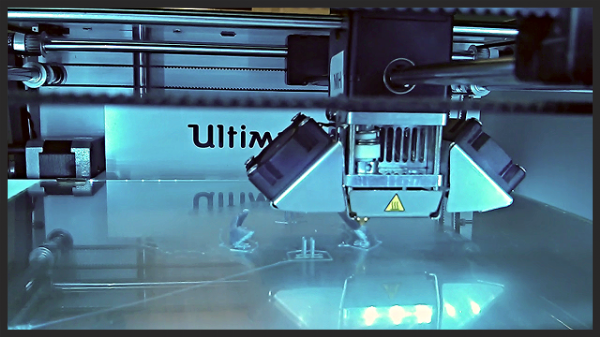

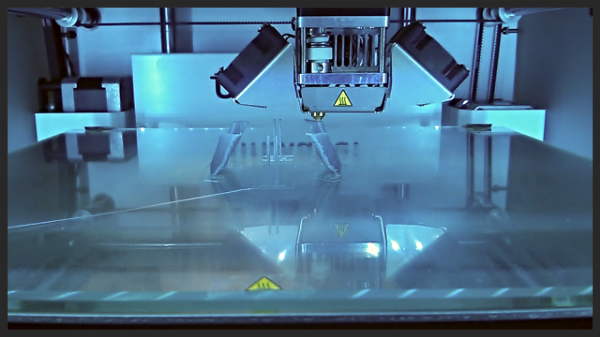

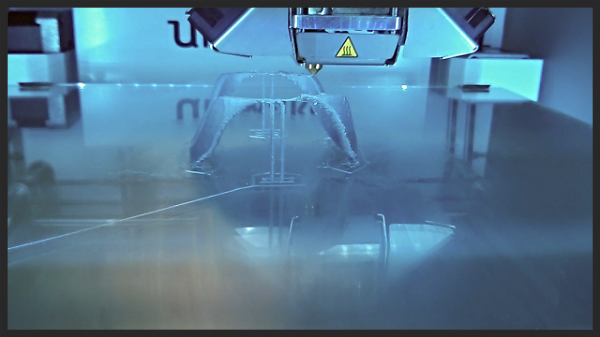

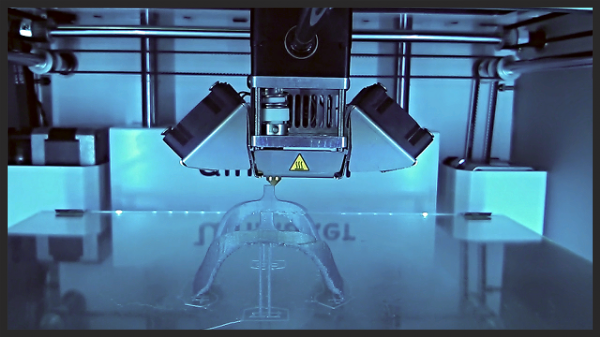

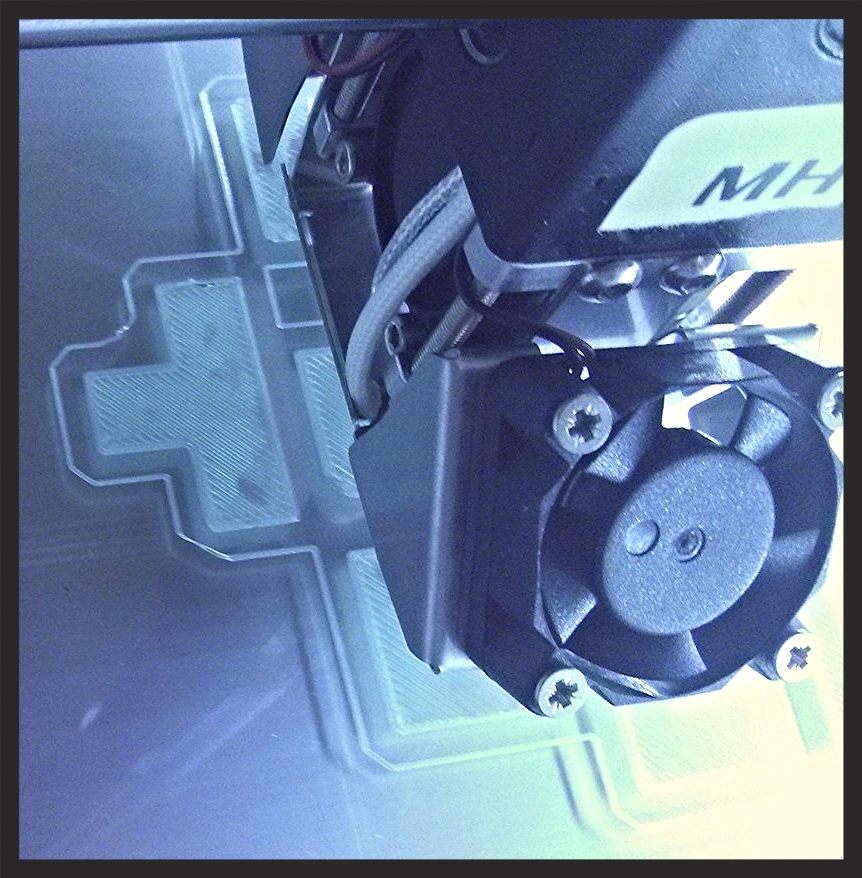

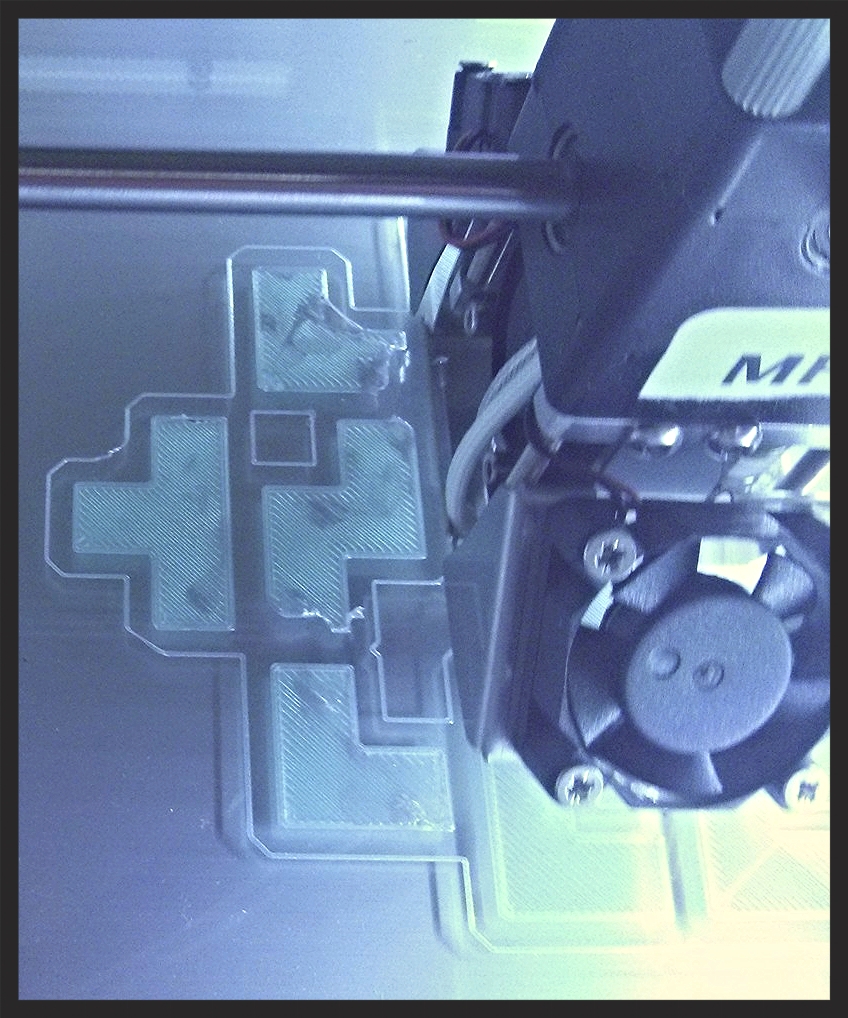

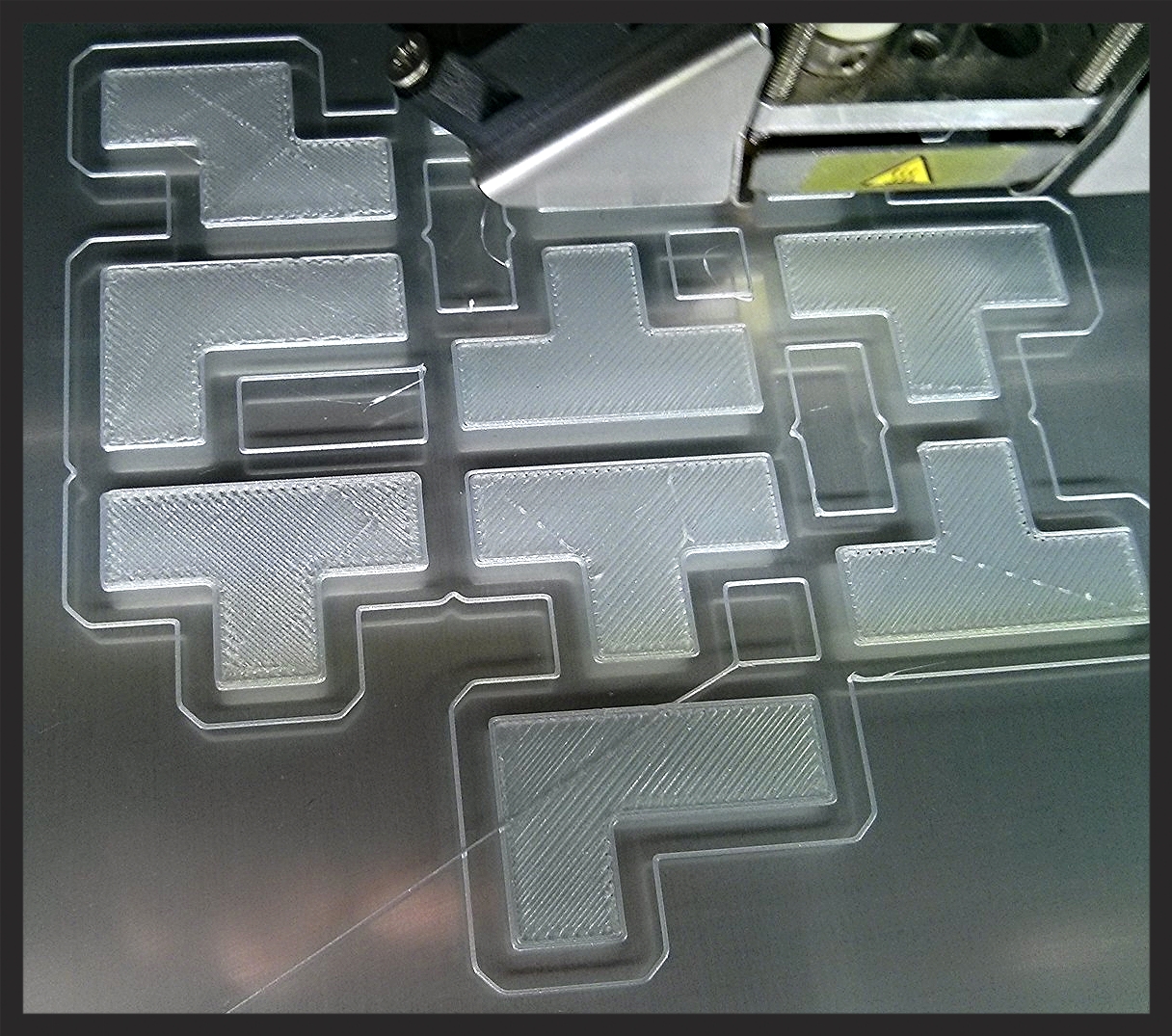

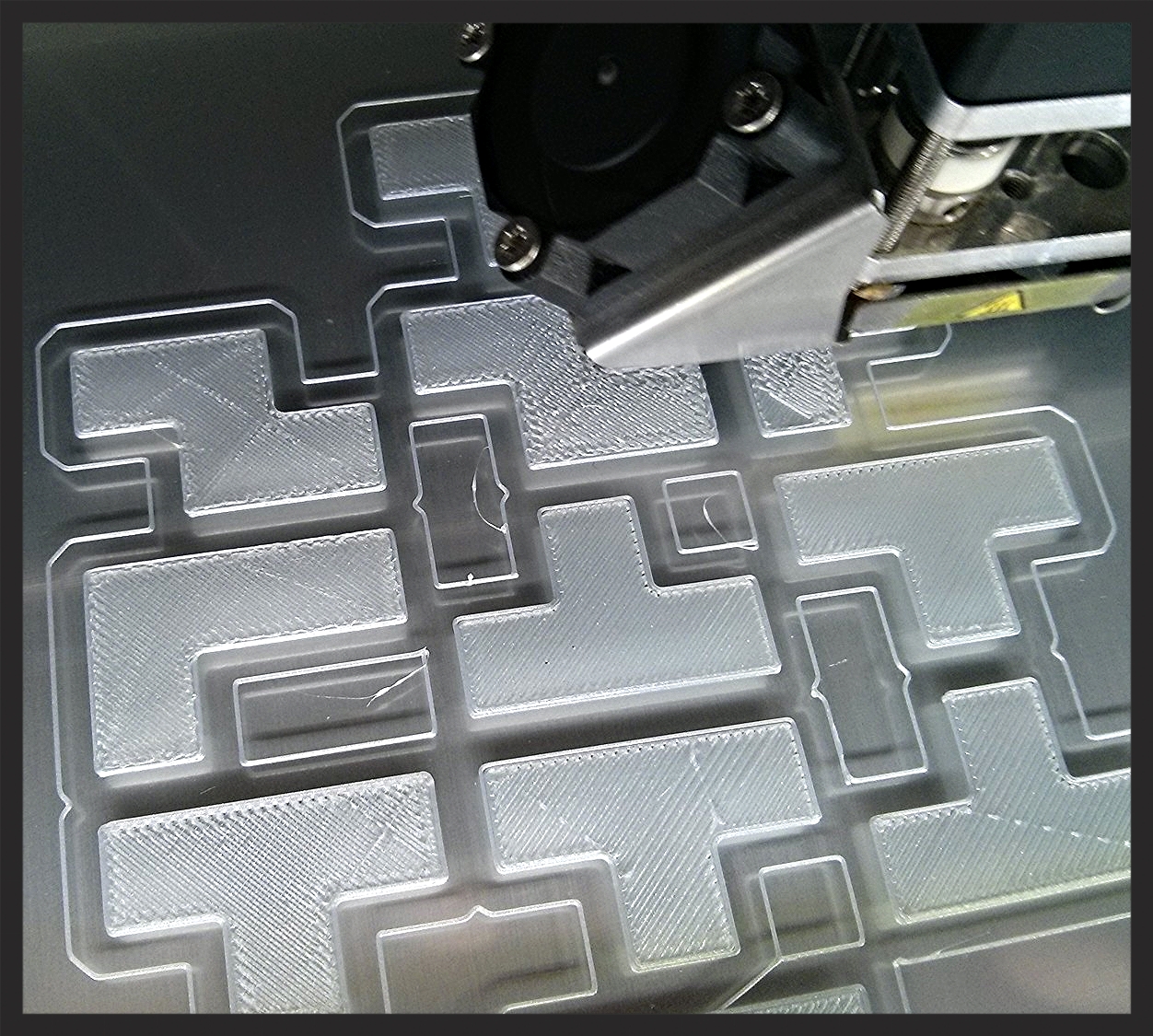

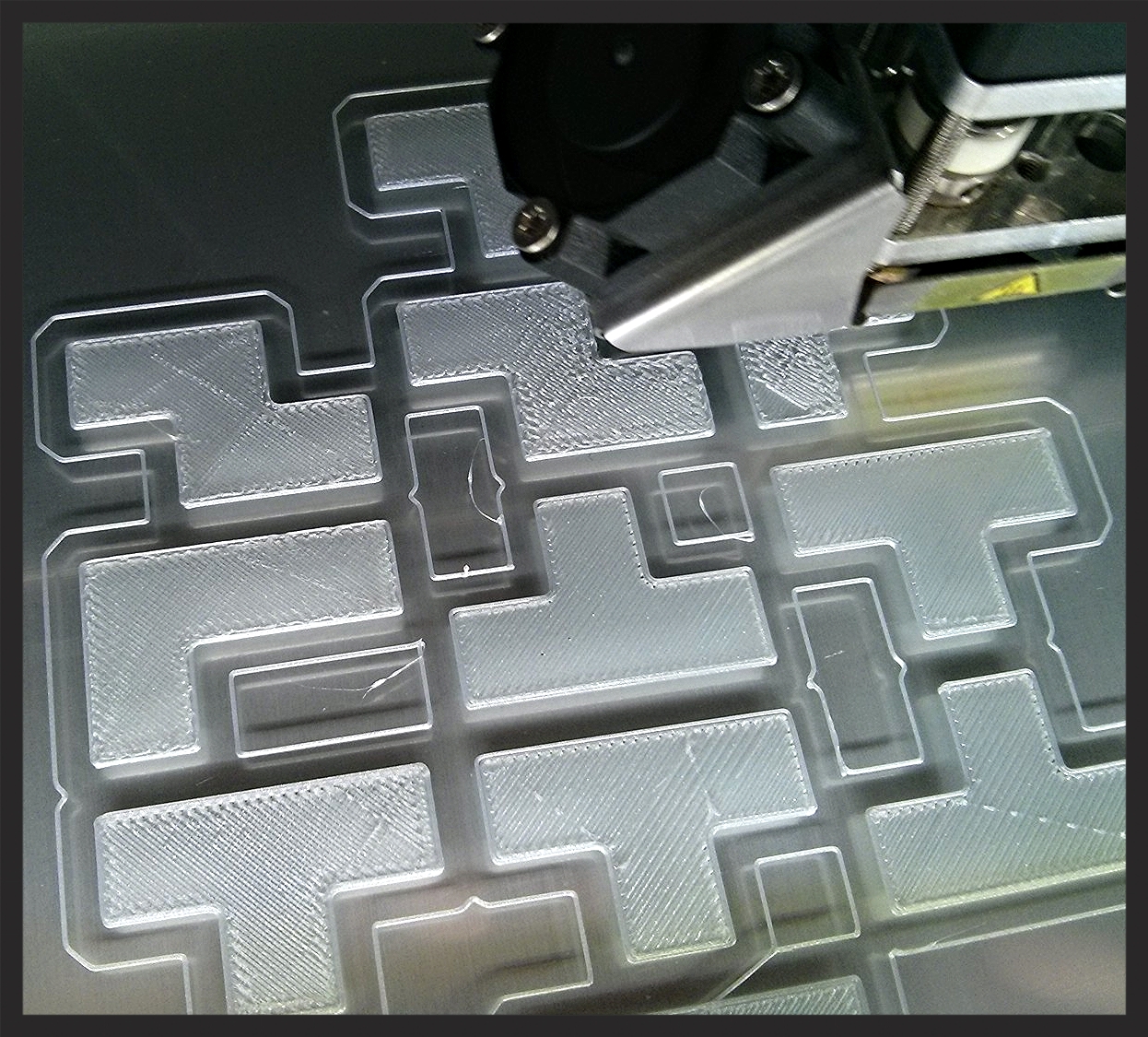

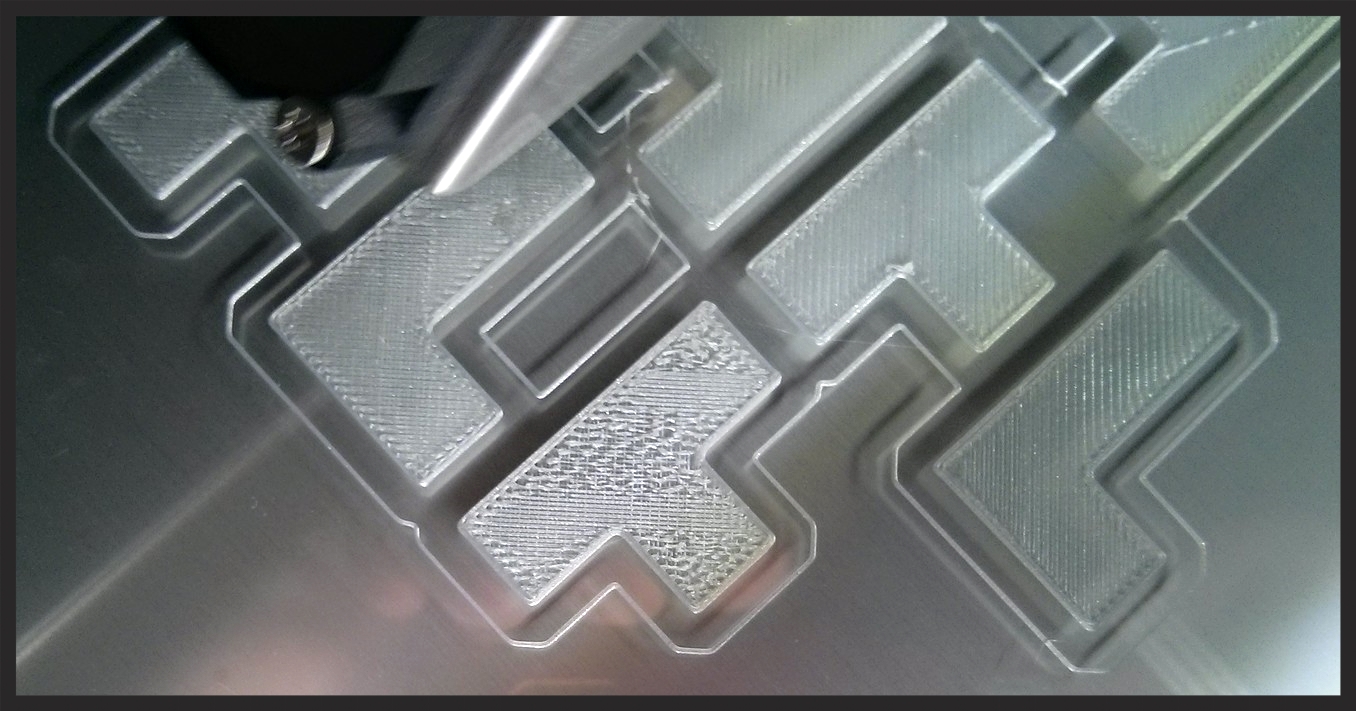

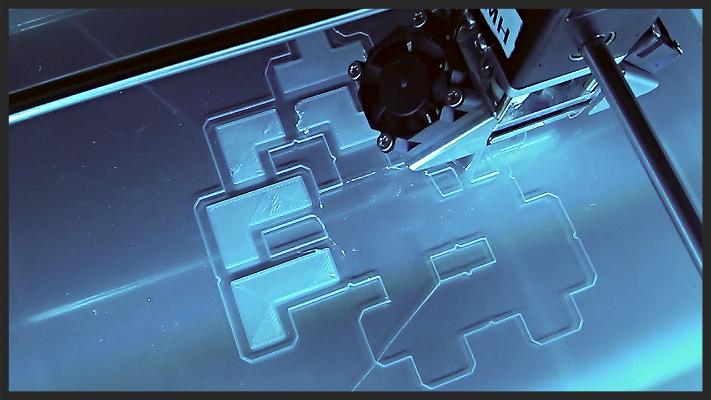

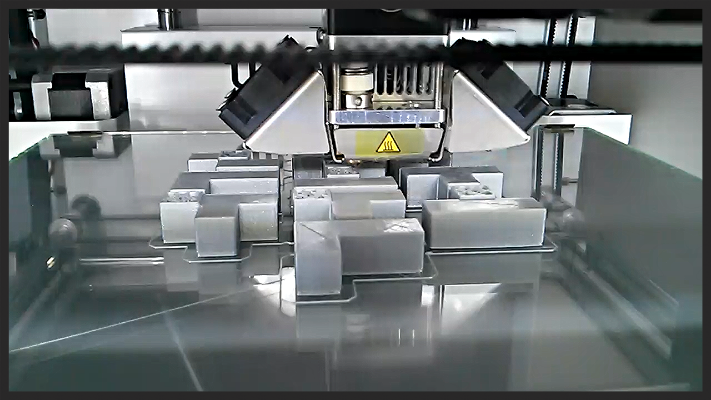

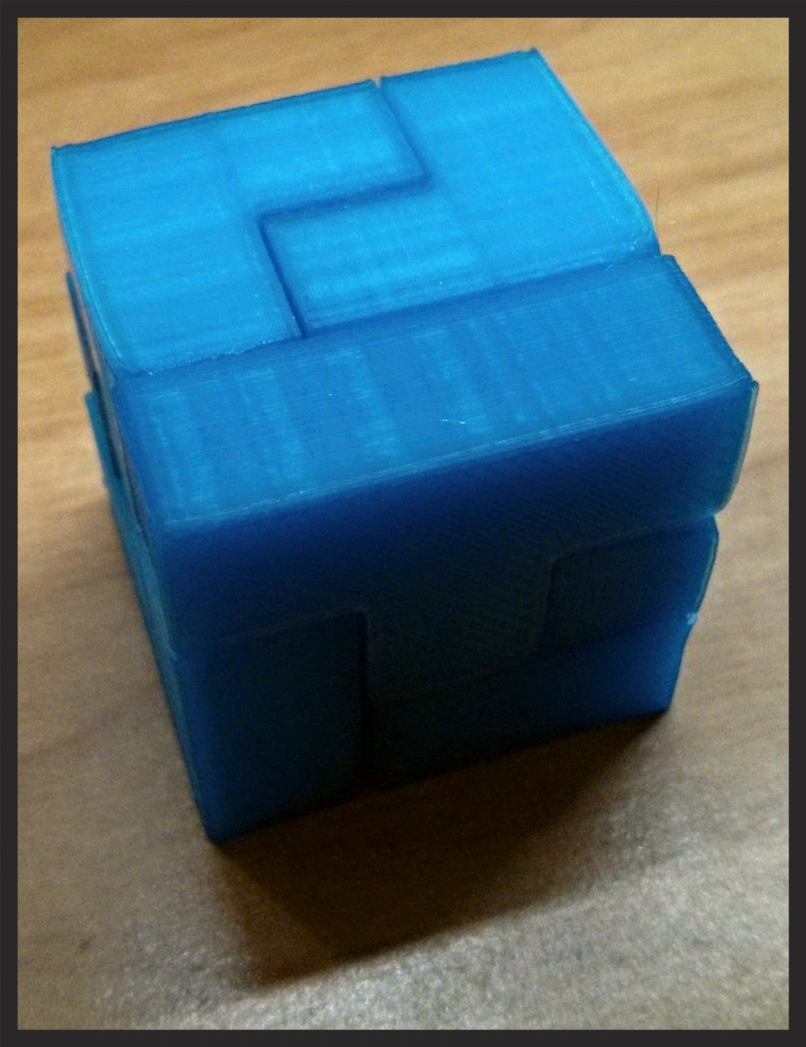

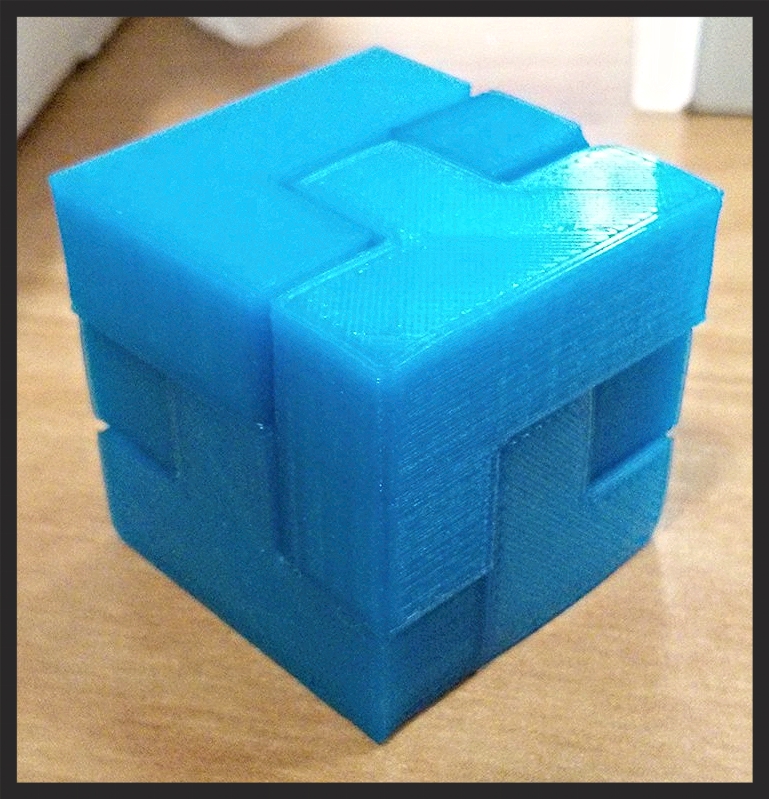

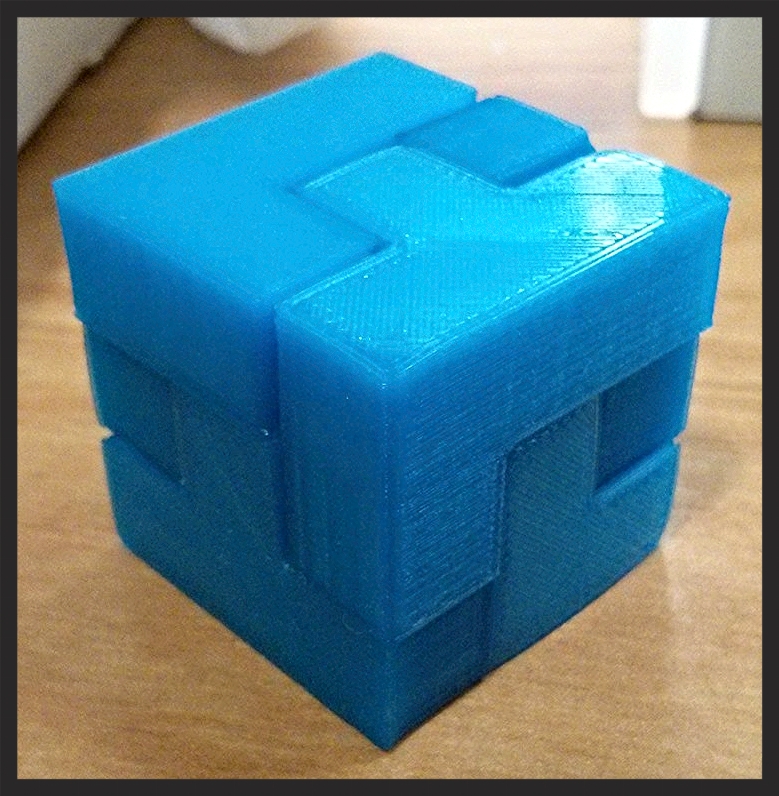

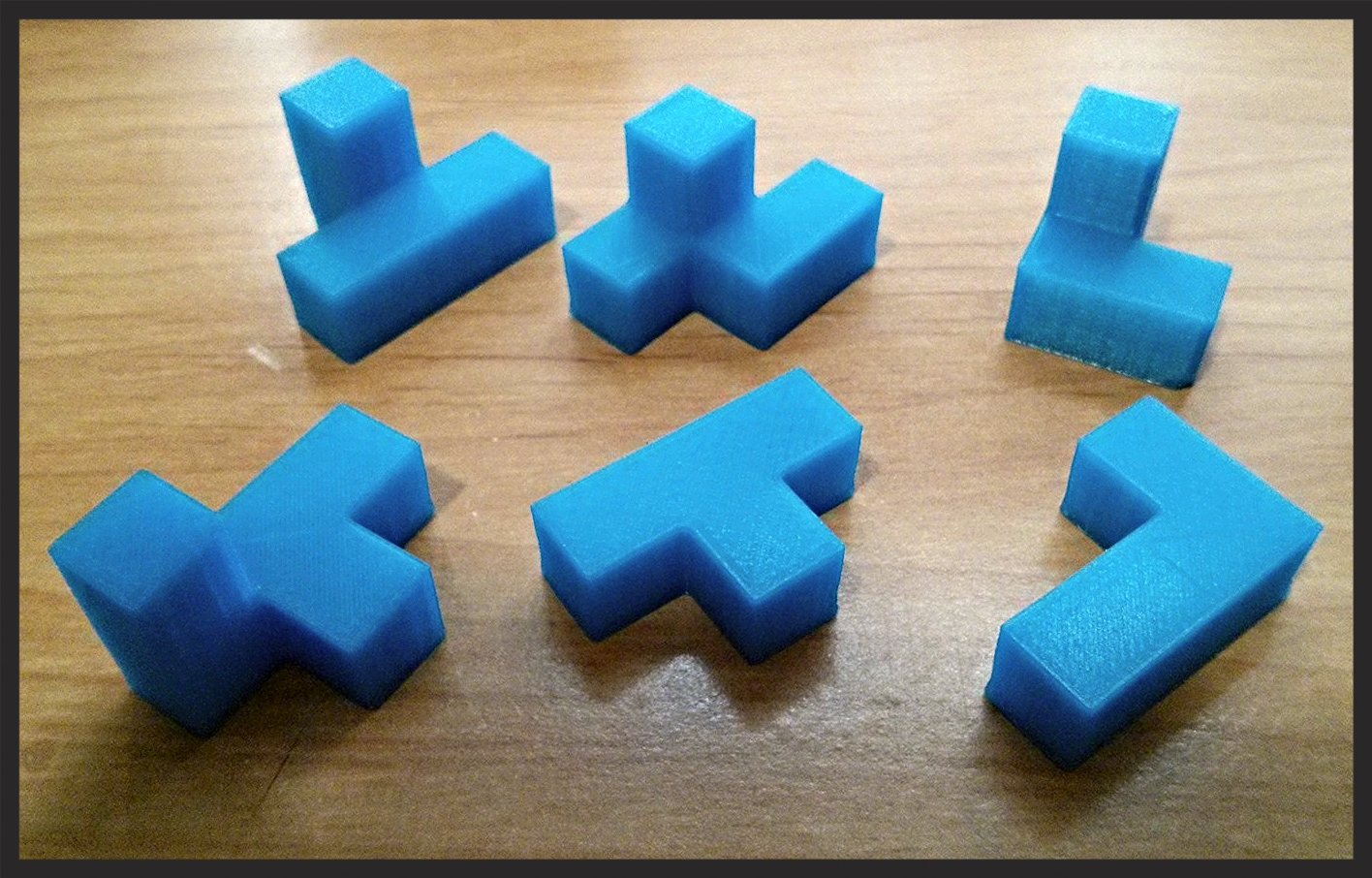

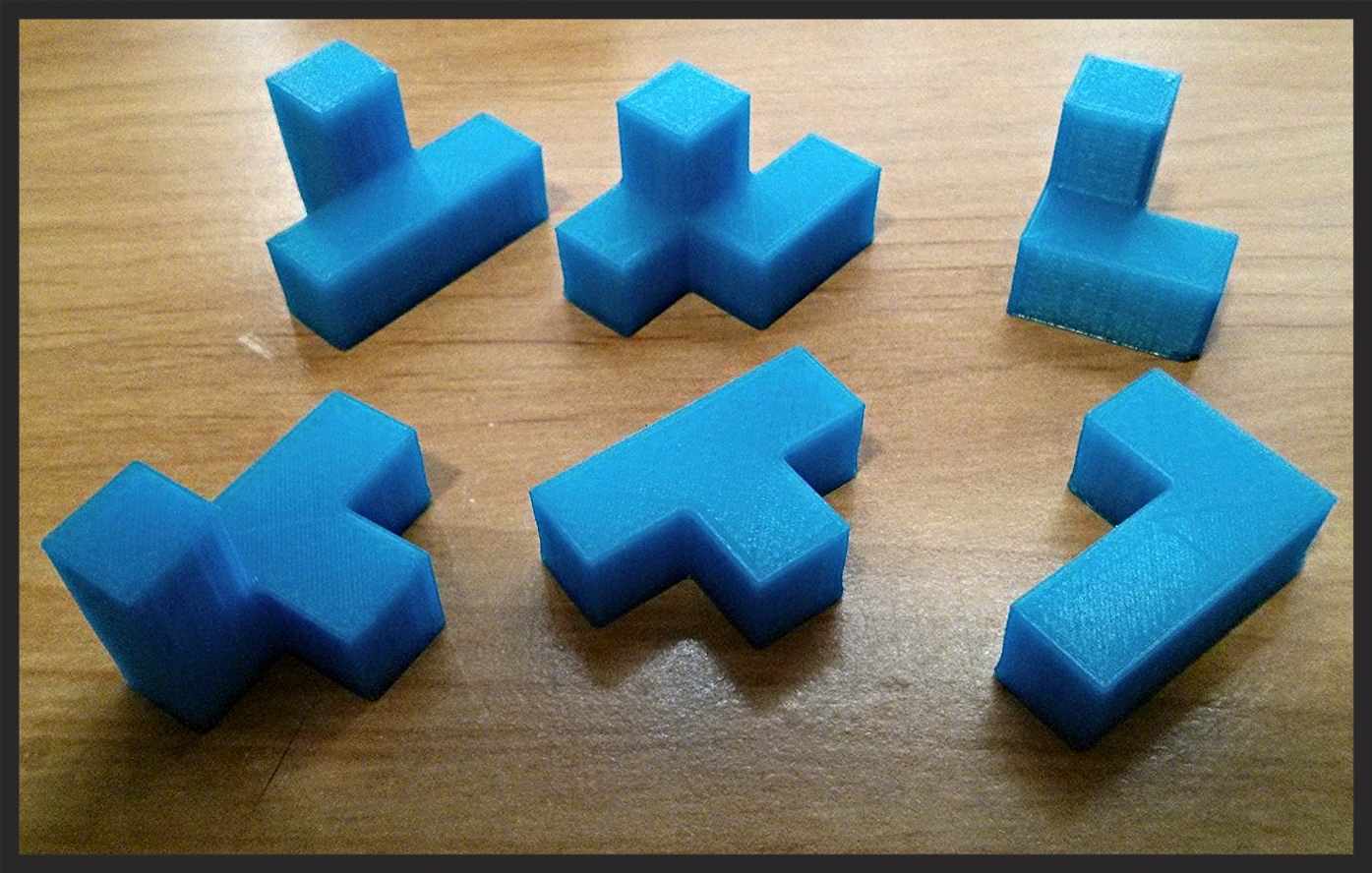

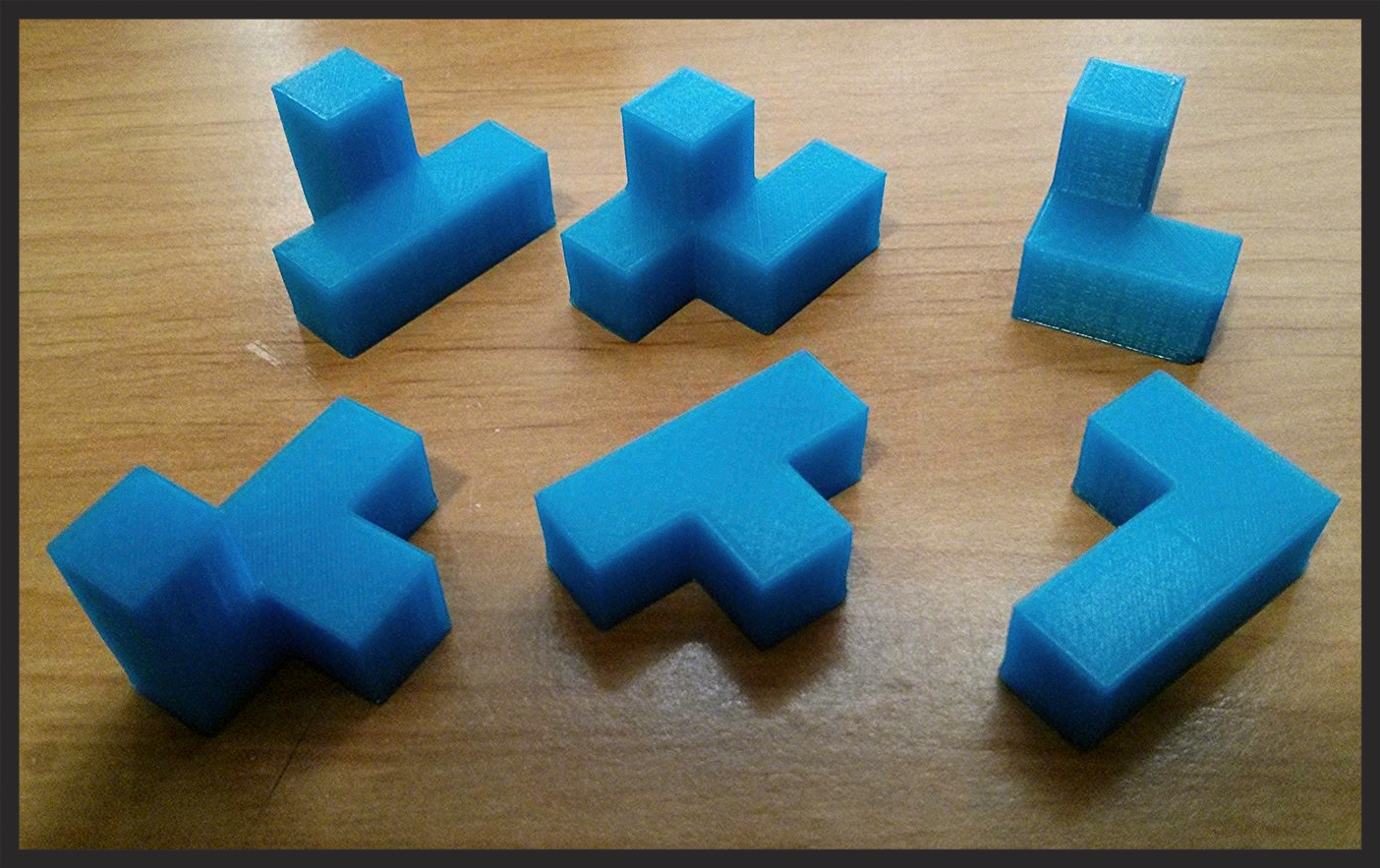

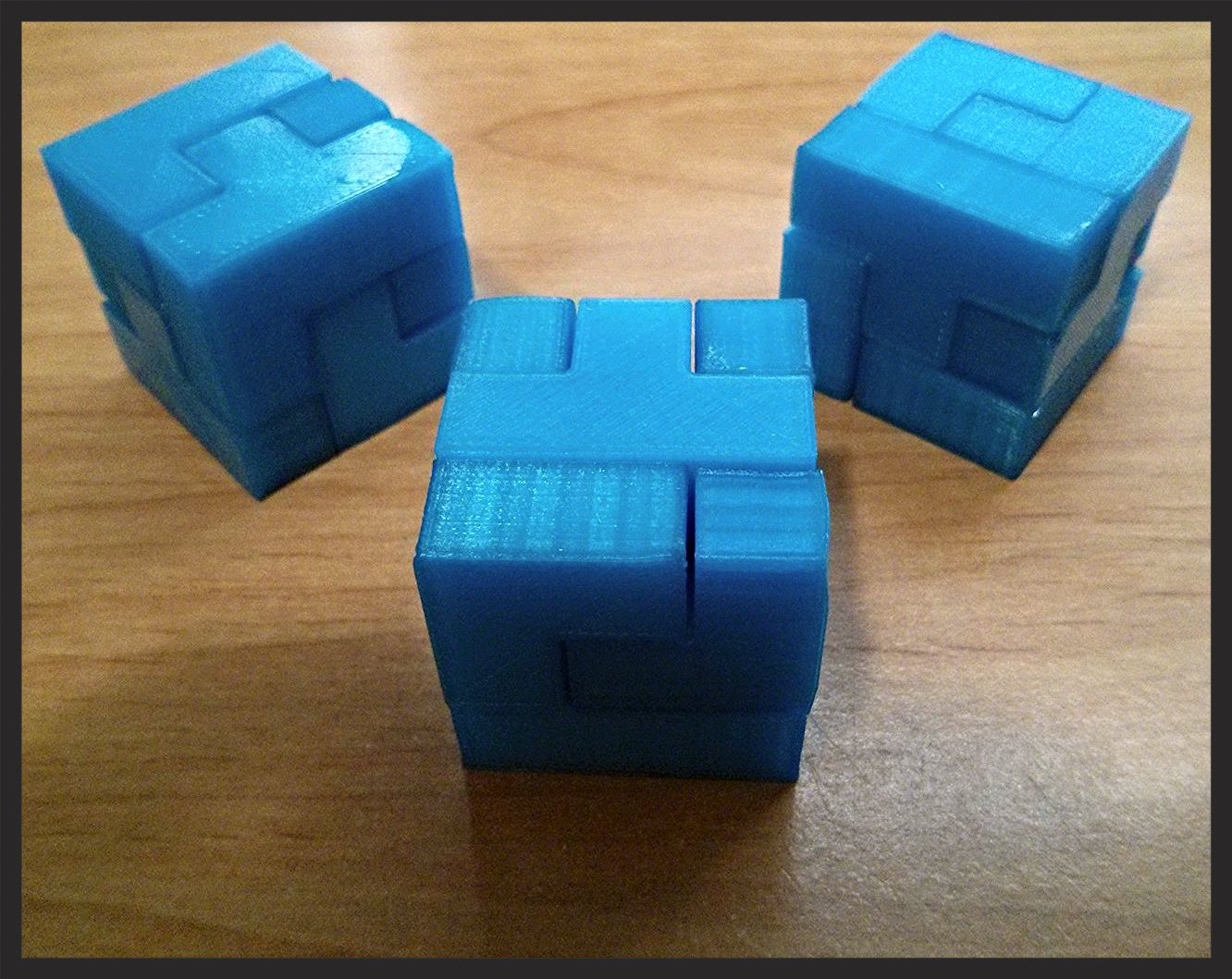

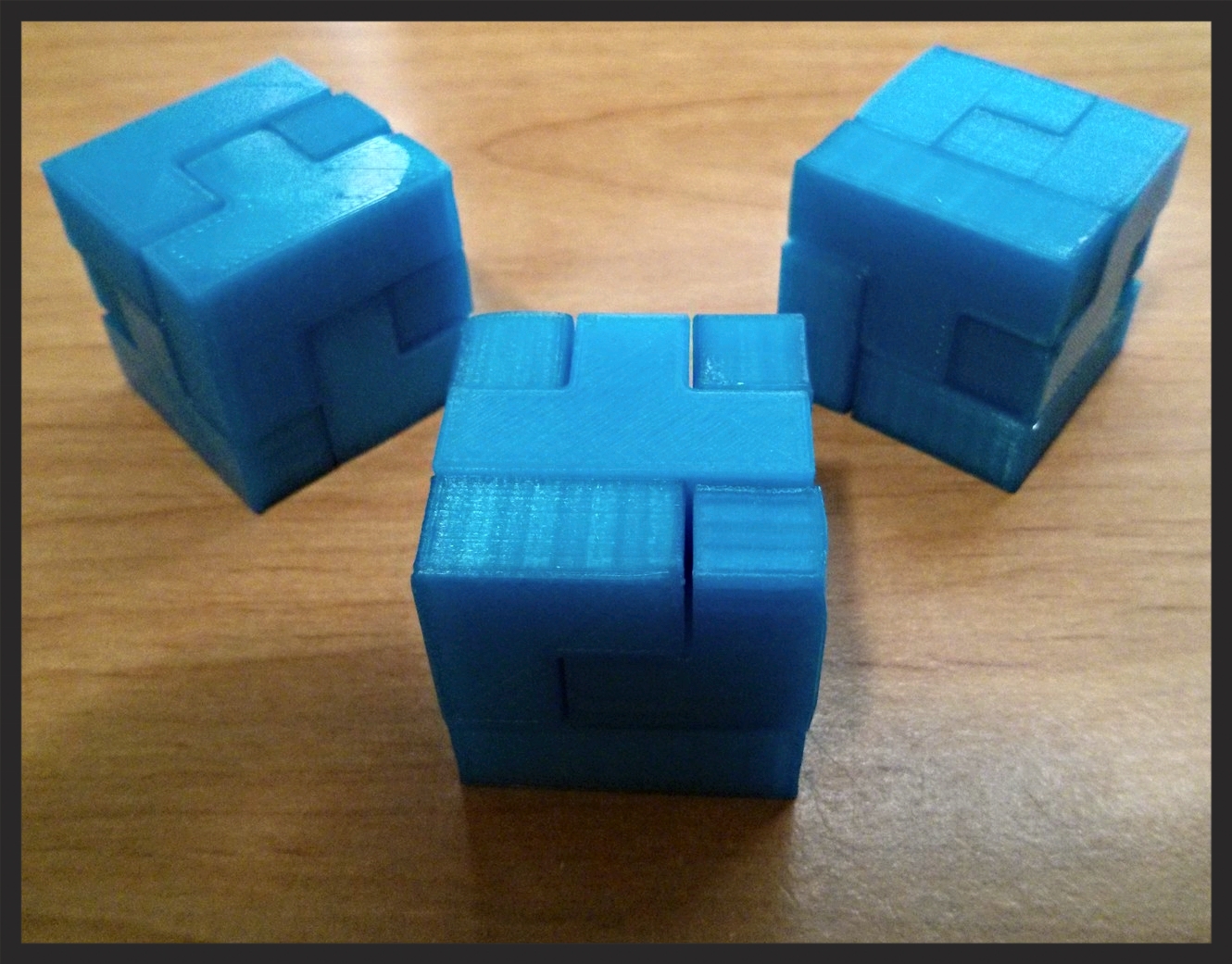

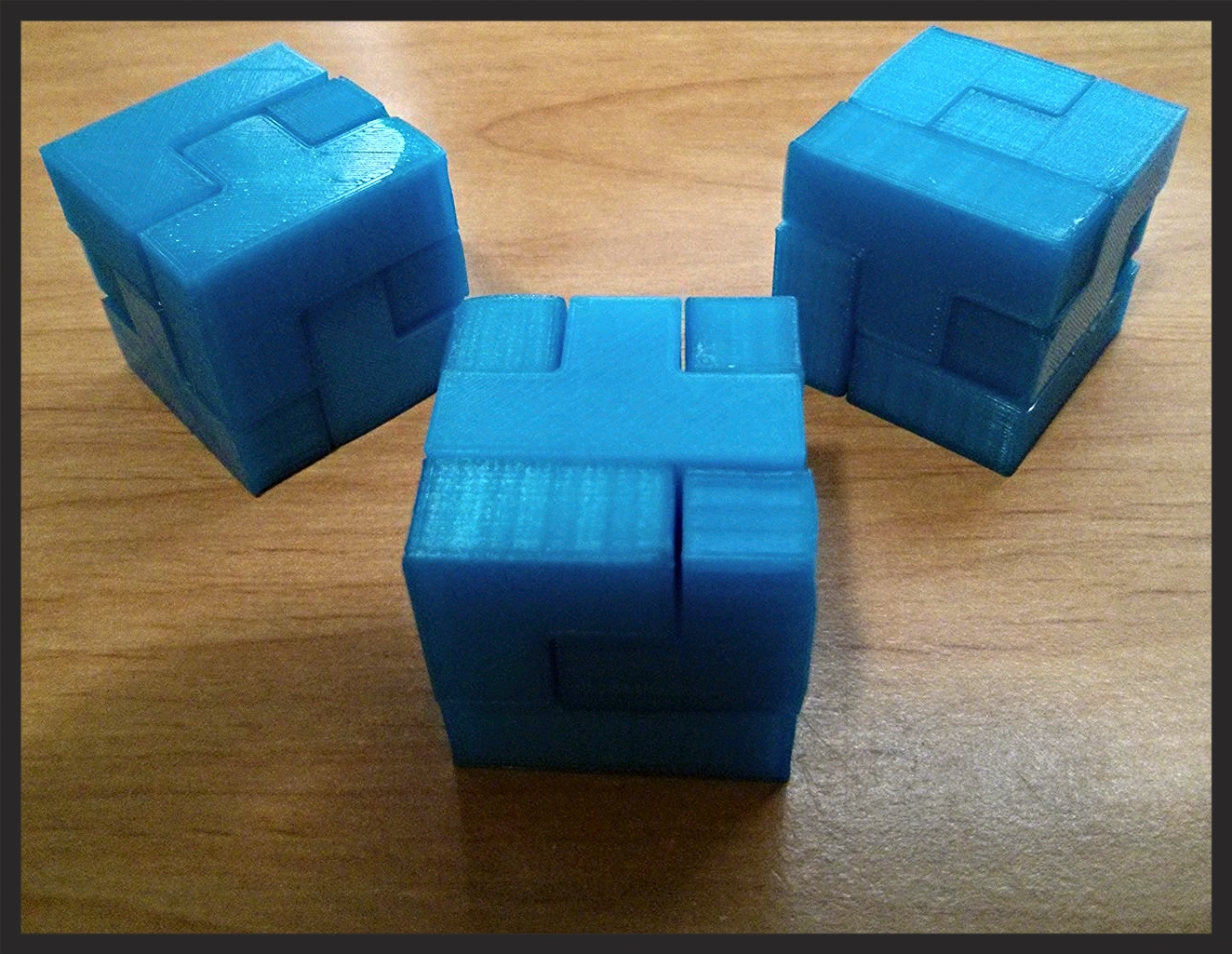

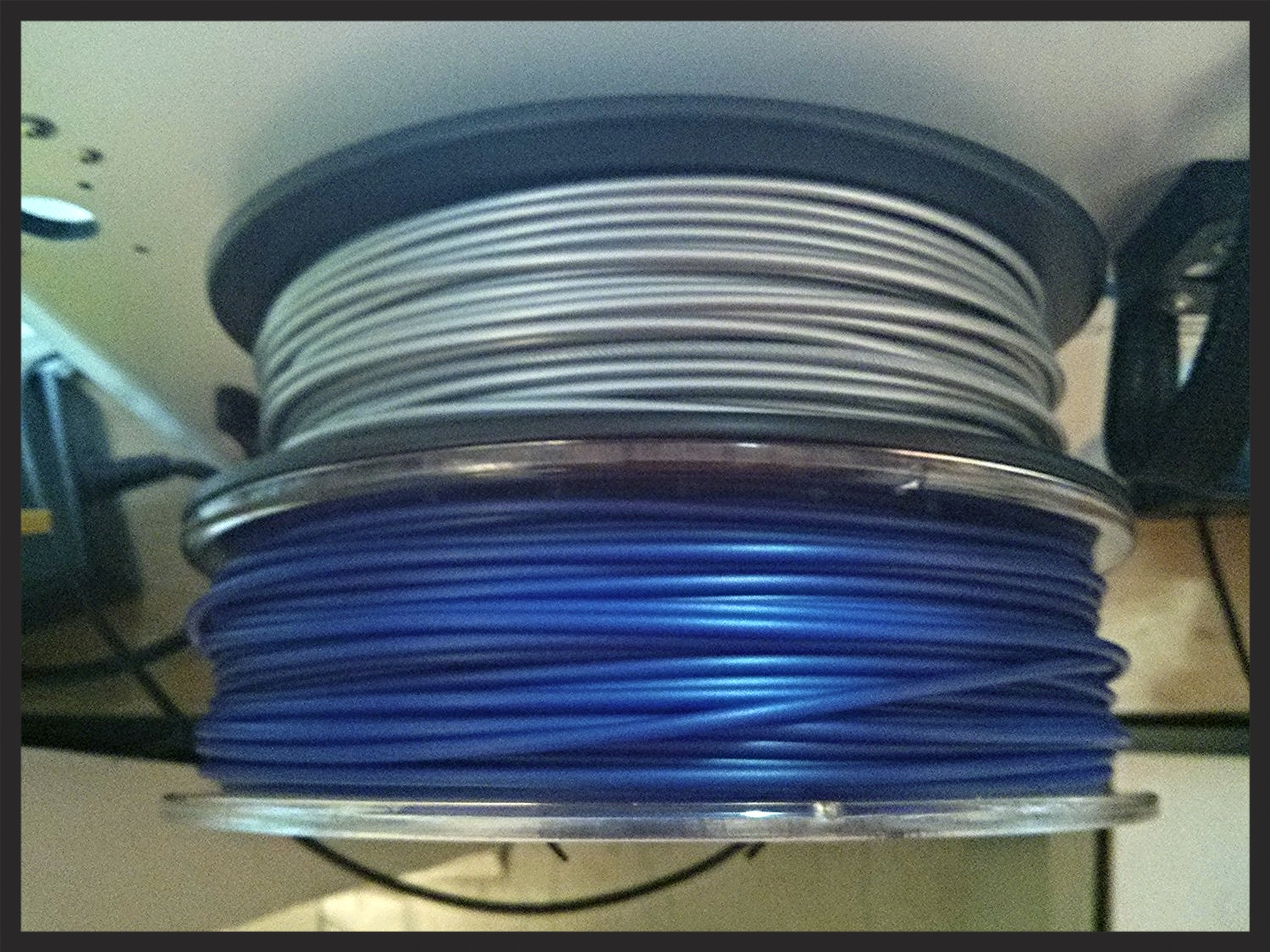

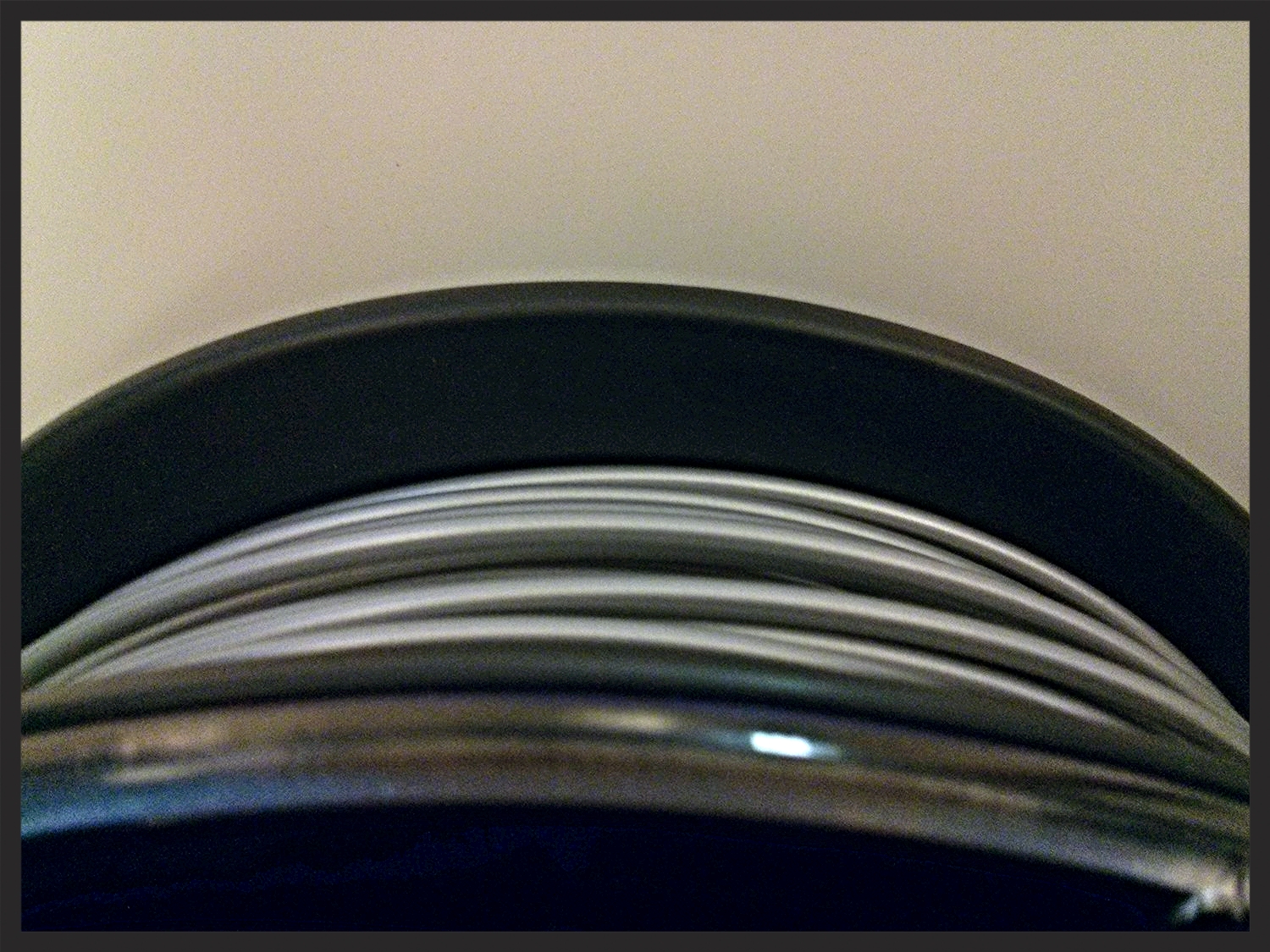

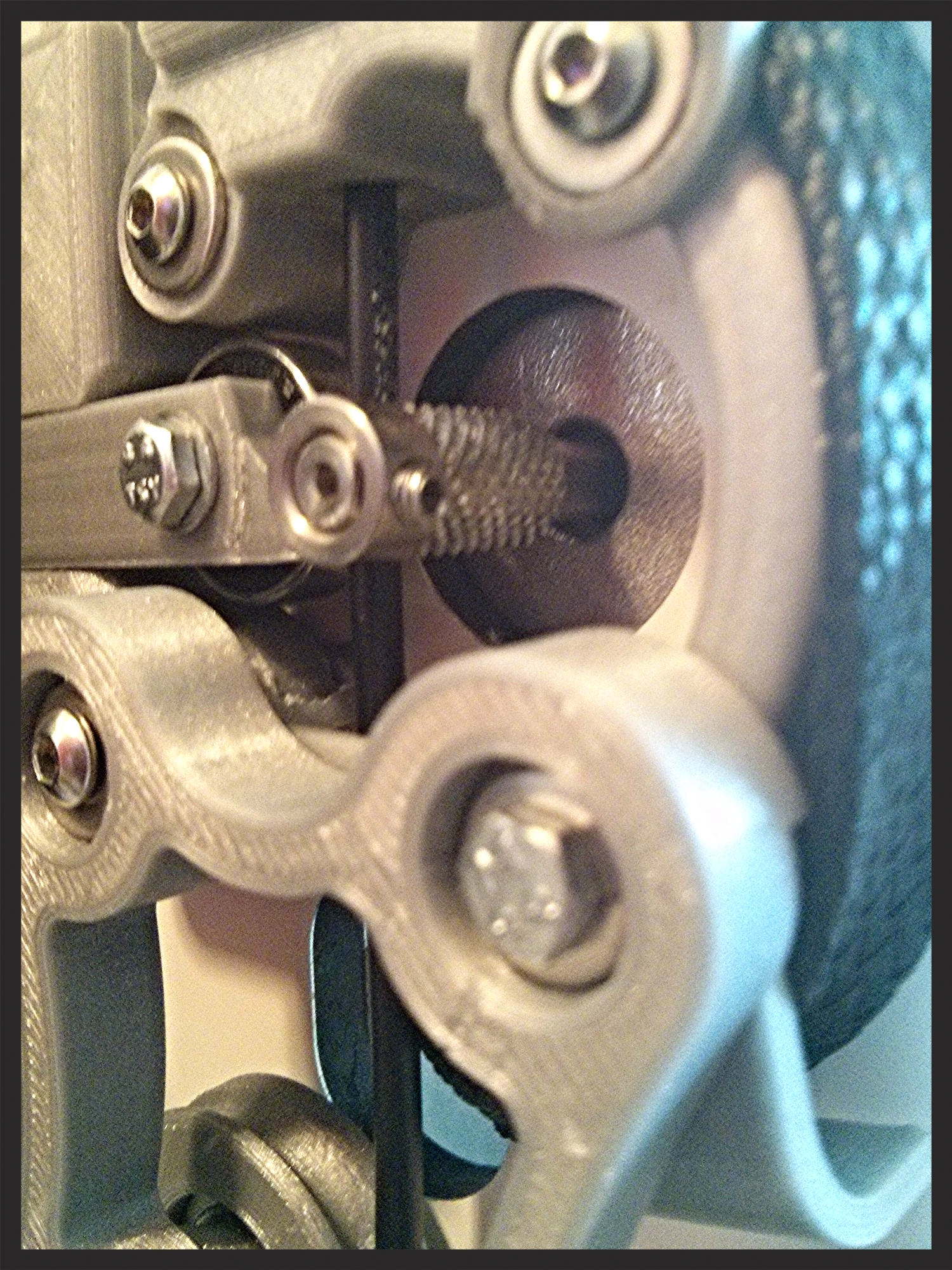

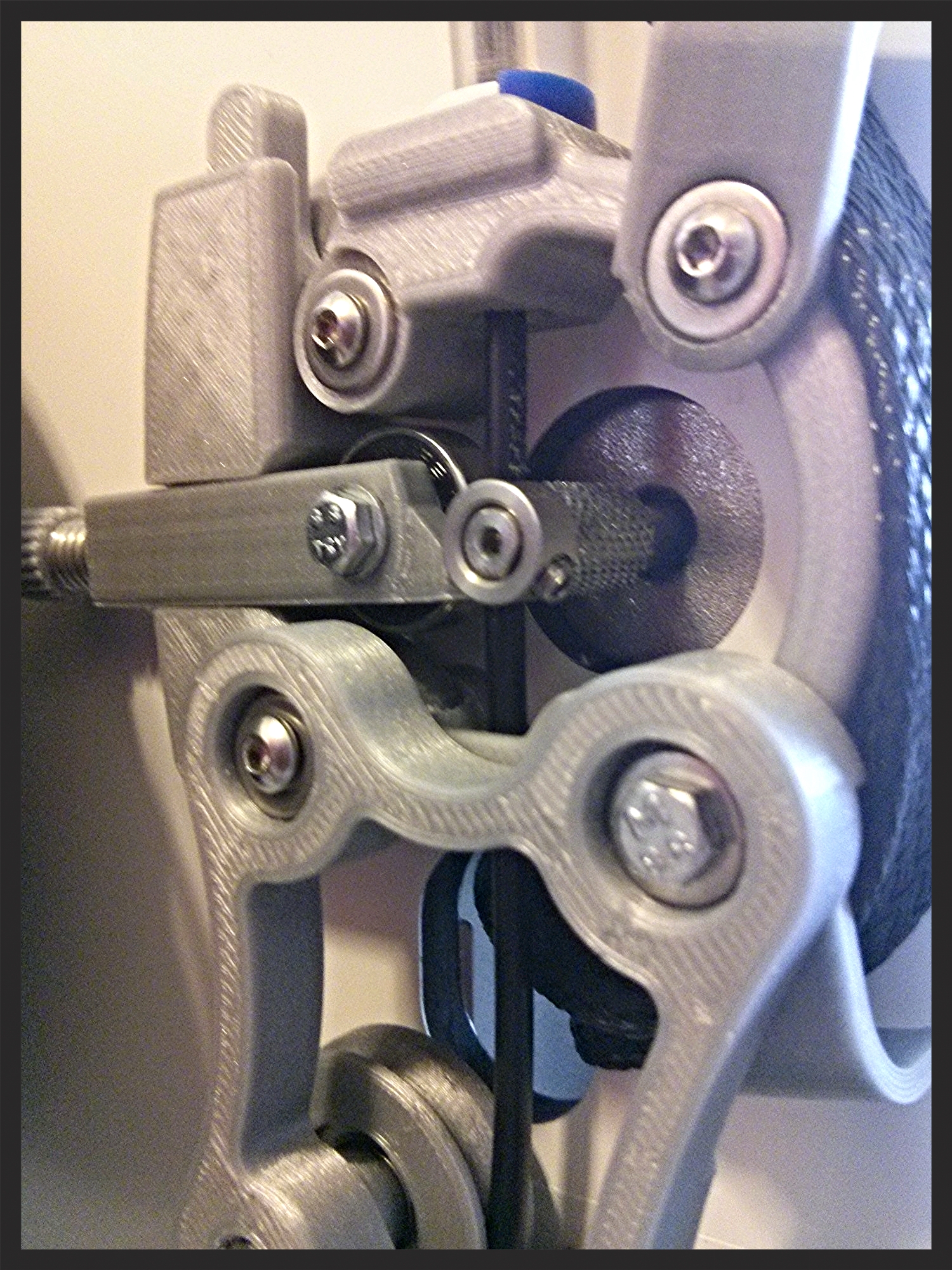

Not long ago, I bought my first 3D printer, an Ultimaker 2 to be specific. So naturally, 3D printing is now one of my current hobbies/passions and is the current focus of a lot of my attention. In this area I want to share some of the things I have made and the knowledge I have learned as I explore and discover the wide world of 3D Printing. I hope you will explore with me! :)